Isotopic Analysis of Solid Samples

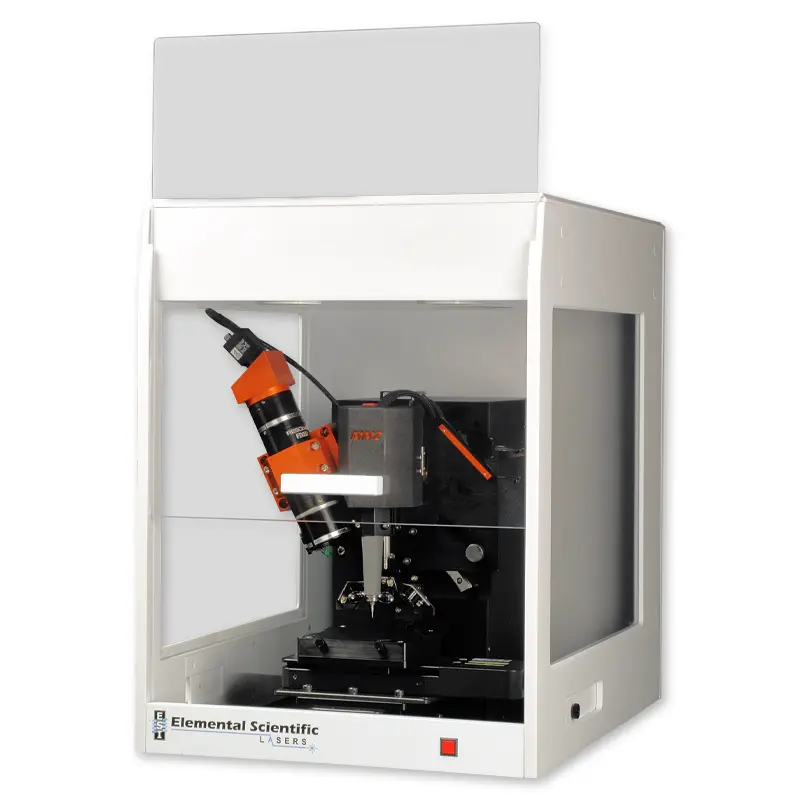

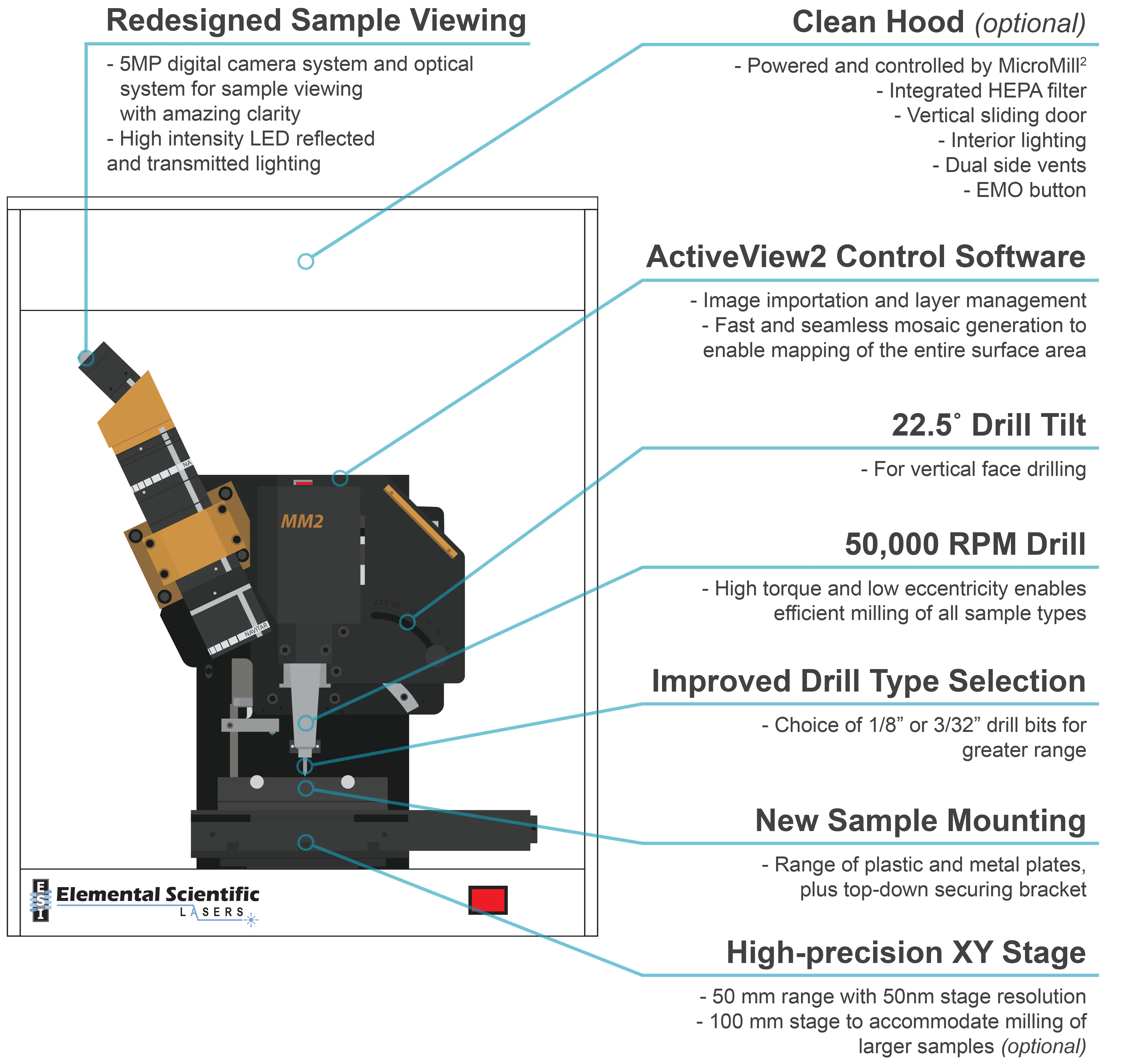

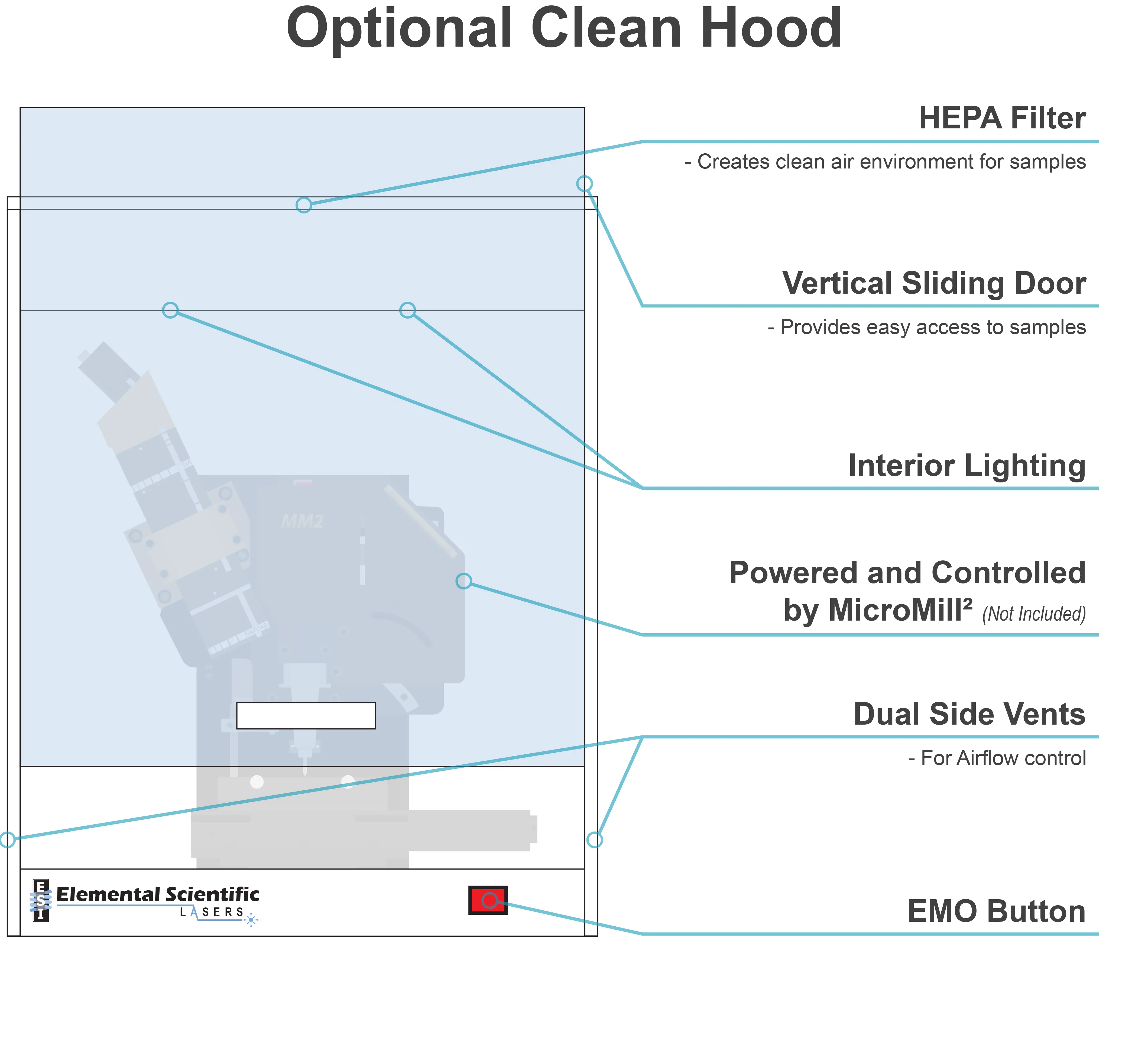

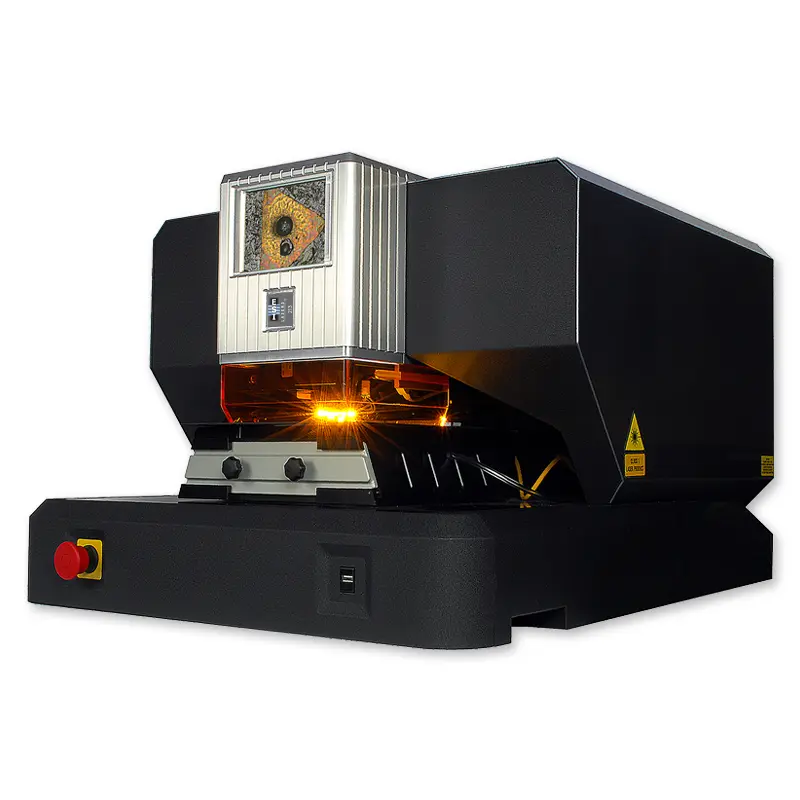

MicroMill2 is a microsampling device designed for high resolution milling to recover sample powder for chemical and isotopic analysis. The combination of submicron stage resolution and positional accuracy, real-time video observation and a custom designed software system allows for sampling of complex accretionary structures in skeletal and crystalline materials. MicroMill2 has built upon the successful design of the original MicroMill and now includes the revolutionary ActiveView2 control software for improved workflow, high-precision stages and 5MP digital camera technology to bring you closer to your samples. The optional Clean Hood is powered and controlled by the MicroMill2 and includes an integrated HEPA filter, vertical sliding door, interior lighting, dual side vents and EMO button.

Higher sensitivity, improved stability, and less fractionation

APPLICATIONS:

- Complex crystal growth zonation: Subsampling provides high-resolution elemental isotopic chemistries and intra-zonal variations of the crystal structure

- Accretionary growth structure examination: Subsampling within annual growth banding of molluscan shells allows reconstructing seasonal variations present during the life of an organism, such as a clam

- Precise sampling of growth zones in speleothems: determine seasonal changes by precise sampling in complex growth zone profiles

- Sampling from otoliths and bone: evaluate elemental and isotopic composition of bonelike materials through precise milling

MARKETS:

- Environmental

- Paleoclimate research

- Geological

- CNOH analysis

- Elemental analysis

- Layered materials

MATERIALS:

- Rocks

- Minerals

- Glasses

- Ceramics

- Metals

- Alloys

Specifications

HARDWARE:

- High-resolution 5MP USB3 digital microscope with 6.7X to 60X digital zoom, and 12 mm to 42 µm field of view of sample

- Simultaneous live view of sample and drill tip without mechanical movement

- 50mm travel in X, Y and Z stages with nanometer step resolution (100mm XY stage option)

- Open-stage architecture accommodates large samples

- Drill tip can be angled up to 22.5˚ for vertical face milling of growth bands

- Software-selectable flood and transmitted LED lighting

- Continuously adjustable (360˚) cross polarizers

- Low-eccentricity, high-torque DC milling chuck with variable speed (0 – 50,000rpm)

- Drill chuck accepts 1/8” and 3/32” for easy sourcing of the perfect tip geometry

- Precision tungsten-carbide milling tools for high spatial resolution

- Joystick stage control for manual sample positioning

SOFTWARE:

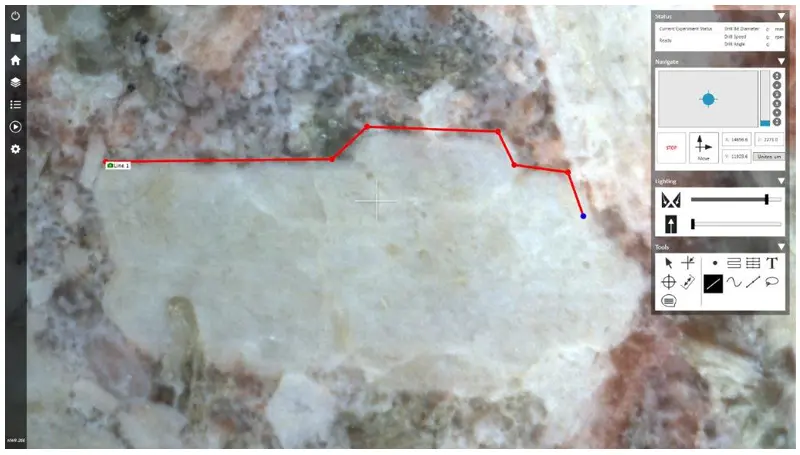

- All new ActiveView2 software digitises the workflow

- Import images from external sources

- Place more scans while drilling is in progress

- Slick point-and-click functionality

- Live video image displayed on computer monitor.

- On-screen display of digitized and interpolated sub-sampling paths

- Precise depth control over entire area of sampling

- Z-tilt correction and contour-following functions

- Off-line digitized files can be read directly with software transformation of image coordinates

- Data record file with sample-path information and estimated sample volumes

- Save, recall and export images (BMP, TIF and JPG files)

Designed with analytical science in mind

- Sub-micron sample motion control

- High-precision milling with angled face drilling

- Sample height detection and tilt correction by a drill-tip sensor, contour-following function

- Sample map navigation increases sample-area field of view

- 50 mm of computer-driven sample movement on X, Y and Z axes

- Data/image file recoordination, including save, recall and export

- Optional Clean Hood